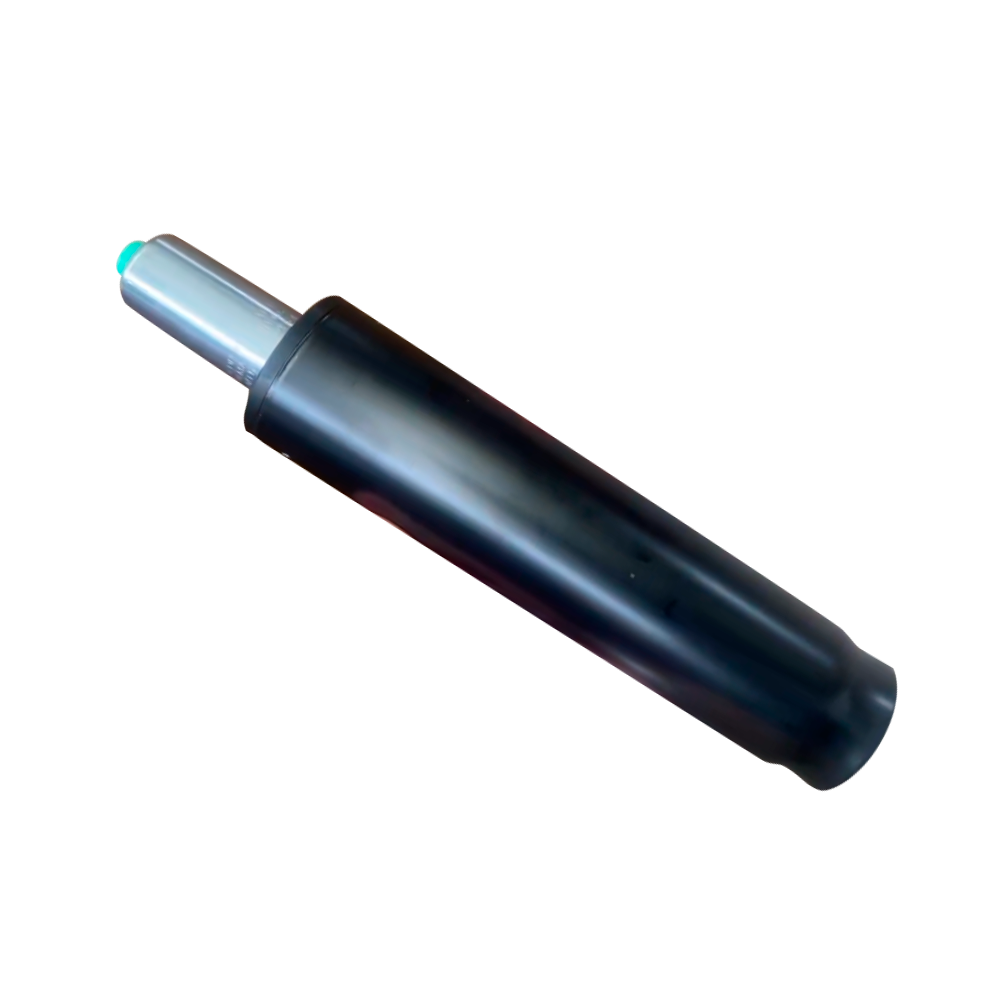

The safety and reliability of the Office Chair Gas Lift Cylinder are issues that users are very concerned about when choosing and using office chairs. Although the gas cylinder provides convenience for adjusting the seat height, it contains high-pressure gas inside. If it is not designed, manufactured or used properly, there may be certain safety hazards. The following is a detailed analysis of the safety and reliability of the gas cylinder from multiple aspects:

Working principle and potential risks

Working principle: The gas cylinder adjusts the seat height through the internal high-pressure nitrogen and hydraulic oil. When the user adjusts the seat height, the gas cylinder uses the pressure of the gas and the movement of the piston to complete the lifting operation.

Potential risks:

If the gas cylinder is not sealed well or is impacted by external forces, it may cause gas leakage or abnormal internal pressure.

In extreme cases (such as overload, high temperature or manufacturing defects), the gas cylinder may burst, releasing high-pressure gas and causing harm to the user.

Safety assessment

Load-bearing capacity

The load-bearing capacity of the gas cylinder is usually graded according to the design standard. For example:

SGS-certified gas cylinders are usually marked with the "SGS" logo, indicating that they have passed international safety tests.

The weight range of standard gas bars is generally 80kg to 150kg, but high-end models may support higher weights.

Users should choose the right gas bar according to their weight and avoid overloading.

Durability test

Gas bars need to undergo rigorous durability tests to ensure their reliability in long-term use. Test items include:

Cycle life test: simulate the gas bar to be repeatedly raised and lowered thousands of times to evaluate its fatigue performance.

Temperature adaptability test: verify the stability of the gas bar under different temperature conditions.

Impact test: check the impact resistance of the gas bar when it is accidentally hit.

Explosion-proof design

High-quality gas bars usually adopt explosion-proof design, for example:

Use high-strength materials (such as cold-drawn seamless steel pipes) to manufacture the outer tube to enhance the structural strength.

Equipped with a safety valve inside to prevent explosion due to overpressure.

The surface of the outer tube is specially treated (such as chrome plating or stainless steel) to improve corrosion resistance.

Factors affecting reliability

Manufacturing quality

Material selection: Low-quality steel or substandard welding processes may cause the gas bar to be insufficiently strong.

Process control: If the sealing or inflation pressure does not meet the standard during the production process, it may cause leakage or failure.

Use environment

Temperature changes: Extreme temperatures (such as high or low temperatures) may affect the performance of the gas rod. For example, high temperature may cause the gas to expand and increase the internal pressure; low temperature may make the hydraulic oil thicker, affecting the smoothness of adjustment.

Humidity and corrosion: High humidity environment may accelerate the corrosion of the outer tube of the gas rod and reduce the service life.

Installation and maintenance

Improper installation: If the gas rod is not installed correctly (such as tilted or loose), it may affect its normal operation.

Lack of maintenance: Long-term lack of cleaning or lubrication may cause wear of the internal parts of the gas rod and affect reliability.

Common problems and solutions

Unsmooth adjustment

Reason: It may be due to changes in the viscosity of the hydraulic oil inside the gas rod or aging of the seals.

Solution: Check the gas rod regularly to see if it needs to be replaced to avoid long-term exposure to extreme environments.

Stuck or unable to adjust

Reason: It may be that the internal parts of the gas rod are damaged or external dust has entered.

Solution: Try to disassemble and clean the gas rod, and replace it with new parts if necessary.

Sudden drop or failure

Reason: The gas rod may be poorly sealed or have internal gas leakage.

Solution: Stop using it immediately and contact a professional to check or replace the gas rod.

Suggestions for improving safety

Purchase quality products

Choose gas rods that have passed international certifications (such as SGS, TUV or ISO) to ensure that they meet safety standards.

Pay attention to the load-bearing rating and applicable range of the product to avoid purchasing inferior or mismatched products.

Proper use

Avoid overloading and operate strictly in accordance with the load-bearing range of the gas rod.

Avoid placing office chairs in high temperature or humid environments to extend the service life of the gas rod.

Regular inspection and maintenance

Regularly check the appearance of the gas rod for scratches, rust or other damage.

If the gas rod is found to be abnormal (such as difficult adjustment or abnormal sound), it should be replaced in time.

Emergency measures

If the gas rod fails (such as sudden drop or stuck), stop using it immediately and take appropriate safety measures (such as sitting on the ground or other supports).

The safety and reliability of the gas cylinder of an office chair depends on its design, manufacturing quality and the environment in which it is used. By choosing quality products, using them correctly and maintaining them regularly, users can minimize potential risks. At the same time, with the development of technology, the safety and user experience of gas cylinders will continue to be optimized and improved.

English

English русский

русский