Temperature variation can significantly impact the operation of lift gas springs due to their reliance on compressed gas and the materials used in their construction. Here are some specific ways in which temperature can affect lift gas springs:

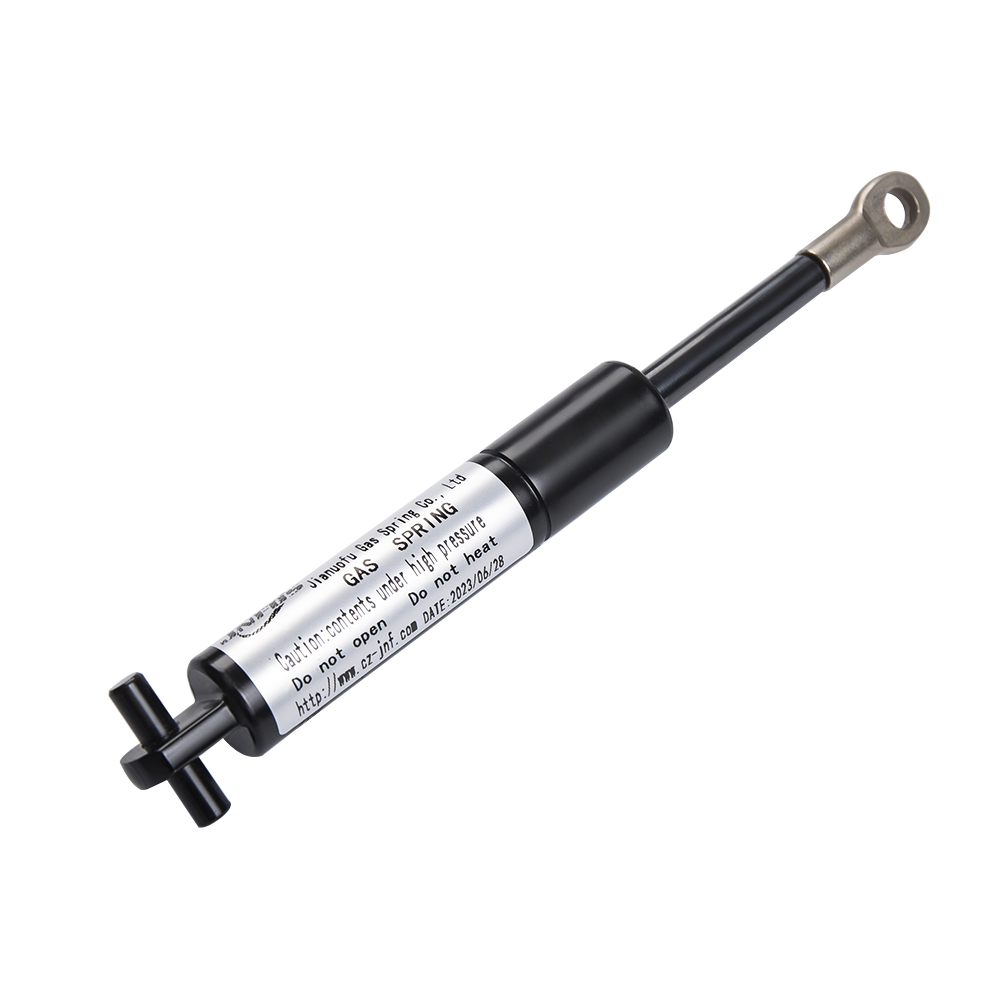

Gas Pressure Variations:Lift gas springs utilize compressed gas (typically nitrogen) to provide force for lifting or supporting loads. Temperature changes can affect the pressure inside the gas spring. As temperature increases, the gas inside expands, increasing pressure, and vice versa. This can alter the spring's force output, potentially affecting its lifting capacity or damping characteristics.

Seal Integrity:Temperature fluctuations can affect the integrity of seals within the gas spring. Seals are crucial for maintaining the gas pressure and preventing leakage. Extreme temperatures, especially cold temperatures, can cause seals to contract or harden, potentially leading to gas leakage or reduced performance.

Material Behavior:The materials used in lift gas springs, such as the cylinder, piston, and seals, can be sensitive to temperature changes. For instance, metals can expand or contract with temperature variations, which might affect the fit and operation of moving parts within the gas spring.

Fluid Dynamics:Gas springs often include hydraulic fluids or grease to facilitate smooth operation and reduce friction. Extreme temperatures can alter the viscosity of these fluids, affecting damping characteristics and overall performance. High temperatures can cause fluid thinning (lower viscosity), while low temperatures can cause thickening (higher viscosity), both impacting operational smoothness.

Performance Consistency:Temperature stability is crucial for maintaining consistent performance of lift gas springs over time. Fluctuations beyond recommended operating ranges can lead to unpredictable behavior, reduced efficiency, or premature wear and failure of components.

Safety Considerations:Extreme temperature conditions can potentially compromise the structural integrity of lift gas springs, especially if materials are not designed to withstand certain temperature extremes. This can pose safety risks in applications where reliable and predictable performance is critical.

To mitigate the impacts of temperature on lift gas springs, manufacturers often specify operational temperature ranges and may recommend protective measures such as thermal insulation, heat shields, or selecting materials that are more resistant to temperature extremes. Regular maintenance and inspection are also essential to ensure seals remain intact and performance parameters are within acceptable limits across varying environmental conditions.

English

English русский

русский