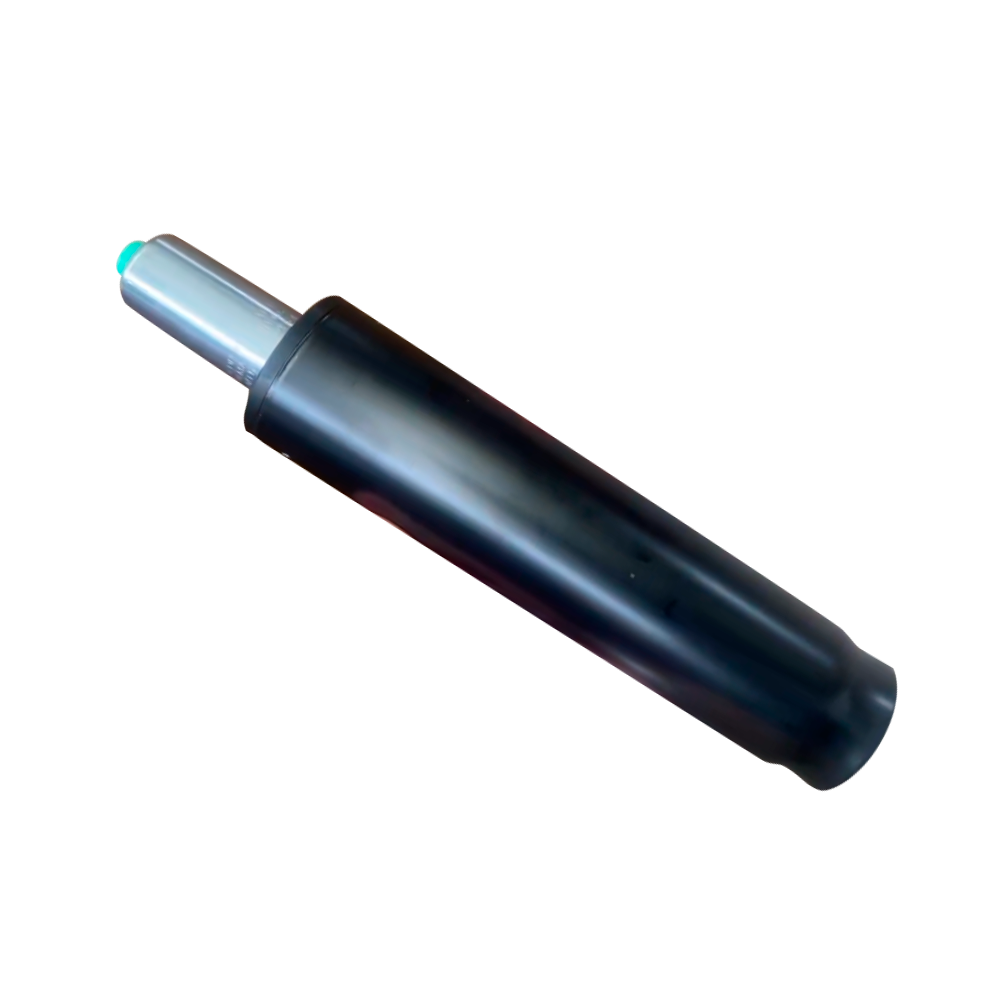

To ensure that the height adjustment of the Office Chair Gas Lift Cylinder is smooth and without obvious jamming, it is necessary to comprehensively consider multiple aspects such as design, material selection, manufacturing process, lubrication maintenance and quality control. The following is a detailed analysis and solution:

1. Optimize the internal structure design

The matching accuracy of the piston and the air chamber:

The core components of the gas cylinder are the piston and the air chamber. The matching accuracy of the two directly affects the smoothness of lifting. If the gap between the piston and the air chamber is too large or too small, it will cause jamming or air leakage. Therefore, it is necessary to ensure that the tolerance range between the piston and the inner wall of the air chamber meets high standards during design.

Shock absorber:

Adding a shock absorber (such as a spring or a buffer pad) inside the gas cylinder can effectively reduce the impact force during lifting and lowering, thereby improving the smoothness of adjustment.

Multi-stage sealing system:

The use of multi-stage sealing rings (such as O-rings and U-rings) can reduce gas leakage and reduce friction, thereby avoiding jamming caused by poor sealing.

2. Choose high-performance materials

High-strength steel:

The outer shell of the gas pressure rod is usually made of high-strength steel (such as chrome-plated steel tube or stainless steel tube). This material not only has good pressure resistance, but also can resist corrosion from the external environment, ensuring long-term stability.

Wear-resistant sealing materials:

The sealing ring is usually made of materials with good wear resistance and low friction coefficient (such as polyurethane or fluororubber). These materials can maintain good sealing performance under high pressure conditions while reducing friction resistance.

Internal lubricating coating:

Special lubricating coating treatment (such as Teflon coating) on the inner wall of the piston and air chamber can further reduce friction and improve the smoothness of lifting.

3. Precision manufacturing process

High-precision machining:

The machining accuracy of the piston and air chamber is crucial to the lifting performance. By using high-precision equipment such as CNC machine tools, the surface finish and flatness of the piston and air chamber are ensured to reach the micron level.

Heat treatment process:

Heat treatment (such as quenching or nitriding) of key components (such as piston rod and housing) can improve their hardness and wear resistance, thereby reducing jamming caused by wear.

Assembly process:

During the assembly process, the installation position and tightening torque of each component must be strictly controlled to ensure that the components inside the gas pressure rod are evenly matched to avoid jamming caused by improper assembly.

4. Gas filling and pressure control

High-quality inert gas:

The inside of the gas pressure rod is usually filled with nitrogen or other inert gases. These gases have stable chemical properties and will not react with the internal metal materials, while providing uniform pressure support.

Precise pressure control:

The pressure of the filling gas needs to be precisely adjusted according to the design load range of the gas pressure rod. Too high or too low gas pressure will affect the smoothness of lifting. For example, too high gas pressure may cause lifting too quickly, while too low gas pressure will cause lifting to be weak.

5. Lubrication and maintenance

Regular lubrication:

Applying an appropriate amount of special lubricating oil or grease to the key parts of the gas pressure rod (such as the contact between the piston rod and the sealing ring) can reduce friction resistance and extend the service life.

Prevent dust from entering:

Dust or impurities entering the inside of the gas pressure rod will increase friction and cause jamming. Therefore, in daily use, you should avoid placing the chair in a dusty environment and clean the outside of the gas pressure rod regularly.

The ultimate goal is to achieve the reliability and comfort of the gas pressure rod under various loads and usage conditions, while meeting the requirements of relevant international standards.

English

English русский

русский