There are indeed different focuses in the design and selection of Push Rod Lifter for Table in home, office and industrial environments. These differences are mainly reflected in load capacity, operating speed, precision requirements, durability and safety. The following is a specific analysis for different scenarios:

Design and selection in home environment

Main use

In the home environment, push rod lifts are usually used for adjustable height dining tables, desks or entertainment equipment (such as TV stands).

The focus is on improving convenience and comfort rather than high-intensity use.

Load capacity

The load of home tables is usually low (50-100 kg), so the load capacity of the push rod lift does not need to be too high.

The design focuses more on lightness and aesthetics to suit the home decoration style.

Operation speed

Home users do not have high requirements for operation speed, and medium speed (about 10-20 mm/s) can meet the needs.

Lower speed can reduce noise and improve stability.

Safety

Safety is one of the key factors, especially in families with children.

The push rod lift should have overload protection and can be manually operated or stopped in an emergency.

Durability and maintenance

The frequency of home use is low, so the durability requirements are relatively loose.

Simple and low-cost maintenance are important considerations.

Design and selection in office environment

Main use

In office environment, push rod lifts are widely used for adjustable desks to support employees to work standing or sitting.

Emphasis on ergonomic design to help reduce health problems caused by long-term sitting.

Load capacity

The load of office tables is usually between 100-150 kg, and a push rod lift with medium load capacity needs to be selected.

The design needs to take into account stability and flexibility to ensure that the table does not shake during the lifting process.

Running speed

Office users have higher requirements for running speed, usually 20-30 mm/s.

Faster speed can improve work efficiency while maintaining stability.

Accuracy and quietness

The office environment is sensitive to noise, so the push rod lift should have a low noise design (less than 40 dB).

High precision is required to ensure that the table remains level at any height.

Durability and maintenance

Office tables are used frequently, so it is necessary to choose products that are durable and easy to maintain.

Equipped with intelligent controllers, the state of the actuator can be monitored and adjusted through software.

Design and selection in industrial environments

Main uses

In industrial environments, actuator lifts are mainly used for heavy workbenches, production line equipment or medical equipment (such as operating tables).

Emphasis on high load capacity and long-term reliability.

Load capacity

The load capacity of industrial actuator lifts is usually more than 200 kg, and even up to 1 ton in some special occasions.

High-power motors and high-strength actuators are required to meet heavy load requirements.

Operating speed

The operating speed requirements of industrial applications vary depending on the specific scenario, usually between 20-50 mm/s.

Fast lifting can improve production efficiency, but safety and stability must be ensured.

Accuracy and repeatability

The industrial environment requires extremely high accuracy, especially when it comes to precision machining or assembly.

Push rod lifts need to be equipped with high-precision sensors and control systems to ensure that the lifting position is consistent every time.

Durability and protection level

Industrial equipment needs to run continuously for a long time, so push rod lifts must have extremely high durability.

The protection level (IP Rating) is usually IP65 or higher to resist the influence of dust, oil and water vapor.

Clear requirements: Determine the load capacity, running speed and accuracy requirements according to the actual application scenario.

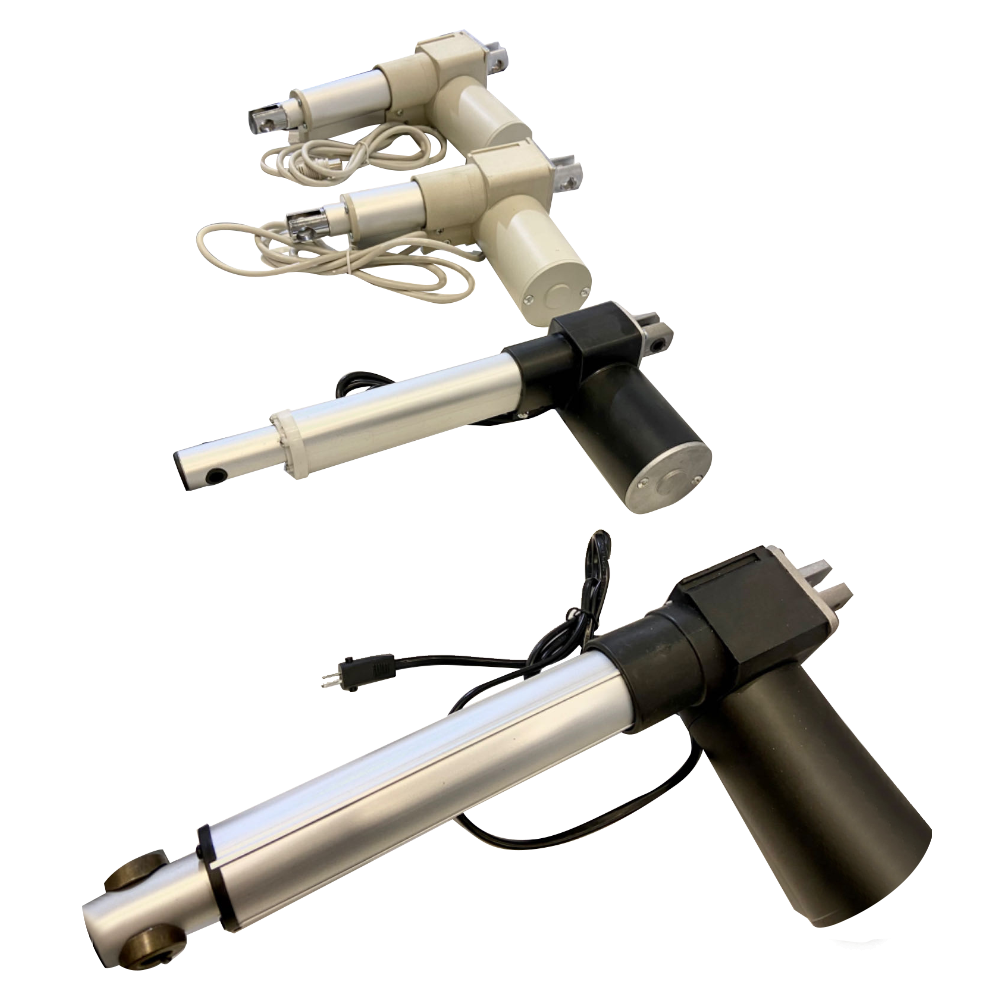

Choose the right type: Electric push rods are suitable for homes and offices, while hydraulic or pneumatic push rods may be required in industrial environments.

Focus on safety: Regardless of the environment, safety is an important factor that cannot be ignored, and products with overload protection and emergency stop functions must be selected.

Consider maintenance costs: Home and office equipment should give priority to products that are easy to maintain, while industrial equipment needs to focus on long-term reliability and maintenance convenience.

From the above analysis, it can be seen that the design and selection of Push Rod Lifter for Table in different environments have different focuses. Only by making reasonable choices according to specific needs can its functions be fully utilized and its service life be extended.

English

English русский

русский